Parts List

- Couplers - Kadee #148 or #142 (see below)

- Fixing screws - 2-56 x 6.35 mm (¼") long, 4 required

- Brass wire - 0.4 mm, 0.6 mm

- Brake hoses - Detail Associate #6206 or Kadee #438, 2 required

- Wheels - 12 mm disc with 26 mm axles, 4 wheelsets required

- Bogies including brass bearings, available from Marbelup Models

- Paint and decals

Removing Support Structures

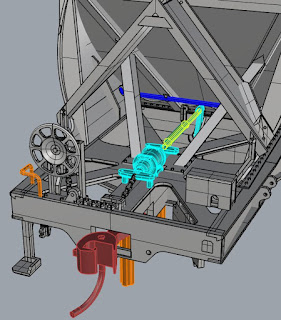

Carefully remove the support structure from the wagon. It is suggested to use a sharp knife to cut the supports away from visible areas. Take particular care around the steps, the brake wheel, and the brake pull rods connected to the end of the brake cylinders (See diagram below.). Note that the steps have guards below them to protect them during production and shipping. It is suggested to leave these guards in place until the majority of the finishing work on the wagon has been completed, to minimise the risk of damage during handling.

|

| Brake Pull Rod - Highlighted in Yellow |

|

| Coupler Spacer |

Go over the model and smooth off any remnants of the fine supports, especially in the visible areas. A sanding stick or small file can be useful for this.

Bogie and Coupler Mounting Holes

The maximum depth for the coupler mounting holes is 2.5 mm. Using a screw which is too long will damage the top surface of the model, so check the screw length and trim if necessary.

Note: An economical source of 2-56 screws in various lengths is Little Bird Electronics.

Bogies

Marbelup Models makes specific bogies for the XBC wagon, as they of a unique design. Two styles of bogies are available: with original, long sideframes or with trimmed sideframes. Both types were used so consult prototype photos to determine which wagons were fitted with which bogies.

The correct wheel size is 12 mm, 26 mm axle length.

Remove the 3D printing supports from the bogies, taking particular care around the brake shoes and other delicate areas.

Clean out the central hole with a 2.3 mm diameter drill bit in a pin vice, to ensure the bogie will pivot freely on its fixing screw.

Place the bogie frame upside-down to insert the wheelsets and brass bearings, with the sideframes resting on supports e.g. styrene or wood strips 2-3 mm thick. (Marbelup Models can provide a 3D-printed jig to support the bogie frame at no cost with purchase of XBC wagons.) Place each wheelset in position and position a brass bearing at the end before pressing the bearings into the recesses in the sideframes using a small, flat-bladed screwdriver or similar. Repeat for the second bearing for each axle. Place the bogie on track of other level surface and check that it rolls freely and does not rock diagonally.

The wheelsets and bearings can be removed subsequently, e.g. for painting, by gently pressing down on the wheelset from above.

|

| Bogie Sideframe Options: Original (left) and Trimmed (right) |

Remove the 3D printing supports from the bogies, taking particular care around the brake shoes and other delicate areas.

Clean out the central hole with a 2.3 mm diameter drill bit in a pin vice, to ensure the bogie will pivot freely on its fixing screw.

Place the bogie frame upside-down to insert the wheelsets and brass bearings, with the sideframes resting on supports e.g. styrene or wood strips 2-3 mm thick. (Marbelup Models can provide a 3D-printed jig to support the bogie frame at no cost with purchase of XBC wagons.) Place each wheelset in position and position a brass bearing at the end before pressing the bearings into the recesses in the sideframes using a small, flat-bladed screwdriver or similar. Repeat for the second bearing for each axle. Place the bogie on track of other level surface and check that it rolls freely and does not rock diagonally.

The wheelsets and bearings can be removed subsequently, e.g. for painting, by gently pressing down on the wheelset from above.

Couplers

The WMC/WMD is designed for Kadee "whisker" couplers using Kadee #262 draft gear boxes. Two options are available, depending on user preference for correct S scale coupler height or the commonly-used HO standard coupler height.

For correct S scale coupler height, use Kadee #148 couplers with the coupler spacer (printed as part of the model) mounted underneath the draft gear box. When assembled, the centre of the coupler should be 12.2 mm above rail height. The coupler height can be checked using a Kadee #206 HO coupler height gauge with a piece of 1 mm thick styrene sheet placed between the rails and the coupler height gauge.

For correct HO standard coupler height, use Kadee #142 "overset" couplers with the coupler spacer (printed as part of the model) mounted above the draft gear box. When assembled, the centre of the coupler should be 9.9 mm above rail height, which can be verified with a Kadee HO coupler height gauge.

Wire Details

Brake Rods

The are four, identical brake rods to be formed from 0.4 brass wire. These are 11.8 mm long (between hole centres), bent 90° at both ends.

Carefully drill out the fine holes in the brake levers. Suggested drill size is 0.45 or 0.5 mm. The holes on the levers closest to the hopper can't be access from above, due to the overflow troughs. Holes have been provided in the bolster, immediately adjacent to the bogie fixing hole, to allow these holes to be drilled out from below. Drill up through the "floor" of the wagon first, then through the brake lever.

As an alternative, to avoid drilling through the "floor", these brake rods can be formed in an L-shape, with a bend at one end only, in which case they simply rest on the inner brake levers. Small bumps have been provided on the inner brake levers to precisely locate the rods. If using this method, the brake rods should approx. 12.25 mm long (centre to end).

Carefully drill out the fine holes in the brake levers. Suggested drill size is 0.45 or 0.5 mm. The holes on the levers closest to the hopper can't be access from above, due to the overflow troughs. Holes have been provided in the bolster, immediately adjacent to the bogie fixing hole, to allow these holes to be drilled out from below. Drill up through the "floor" of the wagon first, then through the brake lever.

As an alternative, to avoid drilling through the "floor", these brake rods can be formed in an L-shape, with a bend at one end only, in which case they simply rest on the inner brake levers. Small bumps have been provided on the inner brake levers to precisely locate the rods. If using this method, the brake rods should approx. 12.25 mm long (centre to end).

|

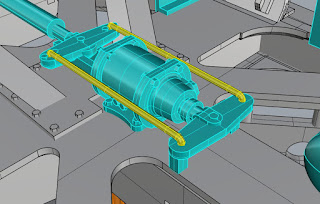

| Brass Brake Rods - highlighted in yellow |

Secure all the wire pieces in position with superglue.

Corner Handrails

Small starter holes have been provided to locate the handrails near the handbrake at each end of the wagon. The handrails can be formed from 0.6 mm brass wire. The holes should be drilled out, e.g. with a 0.65 or 0.7 mm drill bit, to a depth of 2 mm.

Viewed from above, the corner handrails are a symmetrical L-shape, with each leg being 3.5 mm long (centre to centre).

The vertical legs of the handrails should be 5.5 mm long (centre to end), including an allowance of 2 mm to be glued into the fixing holes.

A fixing hole has been provided underneath the coupler opening, as well as a notched bracket towards the left side of the wagon, when view from the end.

The uncoupling lever can be shaped from 0.4 mm brass wire. The diagram below shows the approximate shape to aim for, but feel free to adjust the measurements to suit your model.

After positioning the uncoupling levers, check that the coupler can swing freely and is not obstructed.

Holes are provided next to the couplers on each end of the wagon for air brake hoses. Cast plastic hoses in HO scale are available from Detail Associates, part number 6206, which are suitable in S scale also. Carefully drill out the starter hole provided in the supporting bracket to suit the diameter of the "pipe" on the air hose. The suggested drill size is 0.65 mm.

Similar brake hoses are also available from Kadee, part no #438. If using the Kadee air hoses, the suggested drill size is 0.75 or 0.8 mm.

|

| Corner Handrail |

Viewed from above, the corner handrails are a symmetrical L-shape, with each leg being 3.5 mm long (centre to centre).

The vertical legs of the handrails should be 5.5 mm long (centre to end), including an allowance of 2 mm to be glued into the fixing holes.

Uncoupling Levers

|

| Uncoupler Lever |

The uncoupling lever can be shaped from 0.4 mm brass wire. The diagram below shows the approximate shape to aim for, but feel free to adjust the measurements to suit your model.

|

| Uncoupler Lever Dimensions |

After positioning the uncoupling levers, check that the coupler can swing freely and is not obstructed.

Air Brake Hoses

Similar brake hoses are also available from Kadee, part no #438. If using the Kadee air hoses, the suggested drill size is 0.75 or 0.8 mm.

Weighting

If required, additional weight can be added by gluing lead shot or small pieces of sheet lead in the gap between the bottom of the hopper and the underframe, where it would not be seen in normal operation.

Painting

Either enamel or acrylic hobby paints can be used to paint the finished model. The sample model was airbrushed with Model Master enamel "German Silver Metallic" over Model Master grey primer.

Back to Marbelup Models Home Page